What is IATF 16949:2016?

→ IATF 16949:2016 is an international standard of Quality Management Systems, especially for the Automotive Industry.→ Where IATF_16949 stands for Automotive QMS standard and 2016 refers to the published date.

→ This standard is applicable to all automotive industries irrespective of the scale of the industry.

→ The 1st edition of ISO/TS 16949 was published in 1999 by the International Automotive Task Force (IATF).

→ ISO 9001:2015 is a fundamental requirement of the Quality management system.

→ IATF_16949 includes ISO 9001 and additional automotive industry-specific requirements.

→ This standard was developed and operated by the International Automotive Task Force.

→ This standard gave a common platform for assessment and certification of the supply chain for the automotive industry in the world.

→ The latest Automotive QMS standard 16949:2016 is updated based on the feedback of certification bodies, auditors, suppliers, and OEMs.

→ This standard is easily integrated with other ISO standards such as 14001, 45001, etc.

→ The major focus of this standard is to develop a system that emphasizes continual improvement, defect prevention, and reduce variation & waste in the supply chain.

→ This standard also includes the Customer's Specific Requirements (CSRs) along with the standard's requirement.

→ This standard is fully in line with ISO 9001:2015.

What is the meaning of IATF?

→ The IATF is a group of automotive manufacturers & their respective trade associations.→ Together they have formed a group to provide improved quality products to automotive customers worldwide.

→ The full name of IATF is the International Automotive Task Force and members are Daimler AG, Ford Motor Company, BMW Group, Daimler AG, General Motors Company, PSA Group, Renault, Volkswagen AG, etc.

History of IATF 16949

→ The 1st edition of ISO/TS 16949 was published in 1999 by the International Automotive Task Force.→ This standard gave a common platform for assessment and certification for the supply chain for the automotive industry in the world.

→ Then after 2nd edition was published in 2002 and 3rd edition in 2009.

→ The 3rd edition of ISO/TS 16949:2009 is replaced by IATF_16949:2016 (1st edition).

→ The latest Automotive QMS standard 16949:2016 is updated based on the feedback of certification bodies, auditors, suppliers, and OEMs.

→ This standard is easily integrated with other ISO standards such as 9001, 14001, 45001, etc.

→ The milestones are mentioned below

Major Changes in IATF 16949:2016

→ Addition of OEM's Customer-Specific Requirements (CSRs) with an organization's QMS.→ Another major change is the requirement for safety-related parts and processes

→ In the warranty management process requirement as addressing no trouble found

→ Enlarge the focus on corporate responsibility

→ Give a detailed explanation of supplier management & development requirements

→ Introduced new clause structure as Annex SL high-level structure, it adds process consistency with other ISO standards.

→ Improved product traceability & highlighting the latest regulatory requirements.

→ In this standard introduced the requirements for products featuring embedded software

The IATF 16949:2016 focuses on:

→ Satisfying the customer's requirement and other stakeholder's requirements.→ Promotes the continual improvement

→ focuses on defect prevention

→ Risk-based thinking

→ Integration of customer-specific requirements (CSR's)

→ First and second-party auditor competency

→ Development of products with embedded software

→ Waste and Variation reduction in the whole supply chain

→ Product Safety

→ Manufacturing Feasibility

→ Warranty management

➨ Knowledge of below Five Core Tools,

⇢ PPAP [Production Part Approval Process]

⇢ APQP [Advanced Product Quality Planning]

⇢ SPC [Statistical Process Control]

⇢ FMEA [Failure Mode and Effects Analysis]

⇢ MSA [Measurement Systems Analysis]

➨ Process Approach

⇢ The process approach of the QMS means to define the processes of an organization.

⇢ In other words, we have to define process interactions and required inputs & outputs.

⇢ The purpose of the process approach is to help manage the processes in a systemic way to increase productivity.

⇢ By applying the PDCA Cycle in the process we can get benefits of continual improvement.

⇢ Check how it adds value?

⇢ Measure process efficiency and effectiveness

⇢ Continual improvement of process

➨ Seven Quality Management Principles

⇢ Customer Focus

⇢ Leadership

⇢ Engagement of People

⇢ Process Approach

⇢ Improvement

⇢ Evidence-based decision making

⇢ Relationship Management

Why Implement IATF 16949?

→ Effectively Implemented IATF 16949 make sure that our customers receive constant, good quality products and services.→ It will help us to acquire new businesses.

→ It defines the requirement for a Quality Management System when an organization wants to:

⇢ Clearly show the evidence of its ability to consistently provide products & services that meet customer's requirements.

⇢ Also, meet the applicable statutory, regulatory & product safety requirements.

⇢ Intensify customer satisfaction through the effective implementation of the QMS.

⇢ Implement processes for improvement of the system

⇢ Clearly, state objectives which are specific, measurable, achievable, time-bound & realistic and identify new business opportunities

⇢ Always customers first and make sure that consistently meet their requirement and intensify customer's satisfaction.

⇢ Identify the risks related to your business processes and also take appropriate action to eliminate or minimize the effect of the risk.

The key point for successful implementation of IATF 16949:

→ Understand the all clause wise requirement of ISO 9001:2015 and IATF 16949:2016→ Perform an organizational Gap Analysis against both standards

→ Develop an implementation plan with responsibility and target date

→ Provide training for all relevant personnel

→ Update your existing system

→ Perform internal audit for successful implementation of IATF 16949

Clauses of IATF 16949:2016

- Scope

- Normative references

- Terms and definitions

- The context of the organization

- Leadership

- Planning

- Support

- Operation

- Performance evaluation

- Improvement

[01] Scope

→ Scope - Automotive Supplemental to ISO 9001:2015[02] Normative References

→ Normative and Informative References[03] Terms and Definitions

→ Terms and Definitions for the Automotive Industry[04] Context of the organization

→ 4.1 Understanding the Organization and its Context

→ 4.2 Understanding the Needs & Expectations of Interested Parties

→ 4.3 Determining the Scope of the Quality Management System

⇢ Customer-Specific Requirements

→ 4.4 Quality Management System & its Processes

⇢ Conformance of Products and Processes

⇢ Product Safety

[05] Leadership

→ 5.1 Leadership & Commitment

⇢ General

⇢ Corporate Responsibility

⇢ Process Effectiveness & Efficiency

⇢ Process Owners

⇢ Customer Focus

→ 5.2 Policy

⇢ Establishing the Quality Policy

⇢ Communicating the Quality Policy

→ 5.3 Organizational Roles, Responsibilities, & Authorities

⇢ Responsibility & Authority for Product Requirements & Corrective Actions

[06] Planning

→ 6.1 Actions to Address Risks & Opportunities

⇢ Risk Analysis

⇢ Preventive Action

⇢ Contingency Plans

→ 6.2 Quality Objectives and Planning to Achieve Them

→ 6.3 Planning of Changes

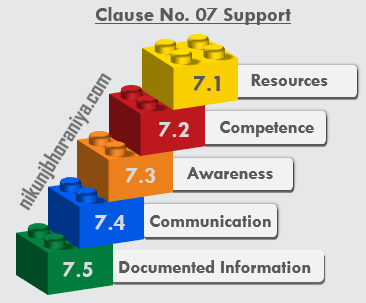

[07]. Support

→ 7.1 Resources⇢ General

⇢ People

⇢ Infrastructure

⇢ Plant, Facility, & Equipment Planning

⇢ Environment for the Operation of Processes

⇢ Monitoring & Measuring Resources

⇢ General

⇢ Measurement Systems Analysis [MSA]

⇢ Measurement Traceability

⇢ Calibration/Verification Records

⇢ Laboratory Requirements

⇢ Internal Laboratory

⇢ External Laboratory

⇢ Organizational Knowledge

→ 7.2 Competence

⇢ Competence – On-The-Job Training

⇢ Internal Auditor Competence

⇢ Second-Party Auditor Competence

→ 7.3 Awareness

⇢ Employee Motivation and Empowerment

→ 7.4 Communication

→ 7.5 Documented Information

⇢ General

⇢ Quality Management System Documentation

⇢ Creating and Updating

⇢ Control of Documented Information

⇢ Record Retention

⇢ Engineering Specifications

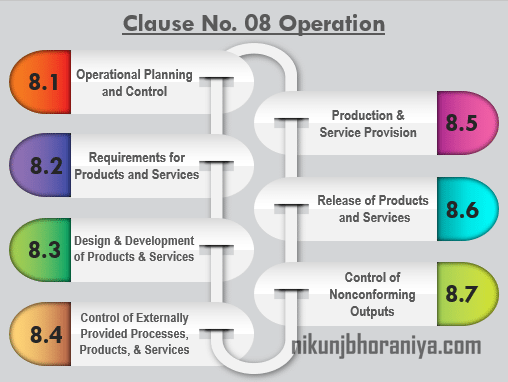

08. Operation

→ 8.1 Operational Planning and Control

⇢ Confidentiality

→ 8.2 Requirements for Products and Services

⇢ Customer Communication

⇢ Determining the Requirements for Products and Services

⇢ Review of Requirements for Products and Services

⇢ Customer-Designated Special Characteristics

⇢ Organization Manufacturing Feasibility

⇢ Changes to Requirements for Products & Services

→ 8.3 Design and Development of Products & Services

⇢ General

⇢ Design and Development Planning

⇢ Product Design Skills

⇢ Development of Products with Embedded Software

⇢ Design and Development Inputs

⇢ Product Design Input

⇢ Manufacturing Process Design Input

⇢ Special Characteristics

⇢ Design & Development Controls

⇢ Monitoring

⇢ Design & Development Validation

⇢ Prototype Program

⇢ Product Approval Process

⇢ Design & Development Outputs

⇢ Manufacturing Process Design Output

⇢ Design & Development Changes

→ 8.4 Control of Externally Provided Processes, Products, and Services

⇢ General

⇢ Supplier Selection Process

⇢ Customer-Directed Sources

⇢ Type and Extent of Control

⇢ Statutory & Regulatory Requirements

⇢ Supplier Quality Management System Development

⇢ Automotive Product-Related Software or Automotive Products with Embedded Software

⇢ Supplier Monitoring

⇢ Second-Party Audits

⇢ Supplier Development

⇢ Information for External Providers

→ 8.5 Production and Service Provision

⇢ Control of Production & Service Provision

⇢ Control Plan

⇢ Standardized Work – Operator Instructions and Visual Standards

⇢ Verification of Job Set-Ups

⇢ Verification After Shutdown

⇢ Total Productive Maintenance [TPM]

⇢ Management of Production Tooling & Manufacturing, Test, Inspection Tooling, and Equipment

⇢ Production Scheduling

⇢ Identification and Traceability

⇢ Property Belonging to Customers or External Providers

⇢ Preservation

⇢ Post-Delivery Activities

⇢ Feedback of Information from Service

⇢ Service Agreement with Customer

⇢ Control of Changes

⇢ Temporary Change of Process Controls

→ 8.6 Release of Products and Services

⇢ Layout Inspection and Functional Testing

⇢ Appearance Items

⇢ Verification & Acceptance of Conformity of Externally Provided Products & Services

⇢ Statutory and Regulatory Conformity

⇢ Acceptance Criteria

→ 8.7 Control of Nonconforming Outputs

⇢ Customer Authorization for Concession

⇢ Control of Nonconforming Product – Customer Specific Processes

⇢ Control of Suspect Product

⇢ Control of Reworked Product

⇢ Control of Repaired Product

⇢ Customer Notification

⇢ Nonconforming Product Disposition

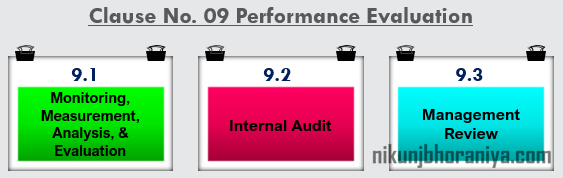

[09] Performance evaluation

→ 9.1 Monitoring, Measurement, Analysis, & Evaluation

⇢ General

⇢ Monitoring & Measurement of Manufacturing Processes

⇢ Identification of Statistical Tools

⇢ Application of Statistical Concepts

⇢ Customer Satisfaction

⇢ Analysis and Evaluation

⇢ Prioritization

→ 9.2 Internal Audit

⇢ Internal Audit Program

⇢ Quality Management System Audit [QMS Audit]

⇢ Manufacturing Process Audit

⇢ Product Audit

→ 9.3 Management Review

⇢ General

⇢ Management Review Inputs

⇢ Management Review Outputs

10. Improvement

→ 10.1 General

→ 10.2 Nonconformity & Corrective Action

⇢ Problem Solving

⇢ Error-Proofing

⇢ Warranty Management Systems

⇢ Customer Complaints & Field Failure Test Analysis

→ 10.3 Continual Improvement

👉 See Also:

Thank you...

ReplyDeleteYou are most welcome

DeleteSir please Share PDF also.. I am always greatfull to you..

DeleteThank you sir for your suggestion we will update it

ReplyDeletesimilarly please post on EMS & OH&S it will be more useful for learners like me

ReplyDeleteThank you for your valuable feedback we will update this also

DeleteSuperb thank you so much for this excellent knowledge 💯📖📚📝

ReplyDeleteThank you for your valuable feedback

DeleteSuperb thank you so much for this excellent knowledge💯📖📚📝

ReplyDeleteIf you have some whatsApp group for sharing the knowledge plz add me

-Abhay Kumar

You can join to out various platform link is available in all pages kindly scroll properly and check

DeletePlease share about Factor tree analysis

ReplyDeleteThank you for your feedback will share you very soon

Deletevery useful information , keep up the good work.

ReplyDeleteThank you for your kind words

DeleteThank you so much 🙏

ReplyDeleteYou are Welcome

DeleteGreat Nikunj

ReplyDeleteThank you for your appreciation

DeleteThanks sir for supporting

ReplyDeleteYou are always welcome!!!!

DeletePlease post AS9100 standard related its will be more usefull for aerspace employees

ReplyDeleteThanks for your suggestion we will work on that.

DeleteThank you for giving excellent knowledge. All topics are arranged in systematic way

ReplyDeleteThanks for your kind words!!

DeleteVery useful work u r doing sir...

ReplyDeleteI'll recommend this site to my colleagues...

Keep up...

Thank you for your valuable feedback we are very happy for that and we are really very thankful to you for sharing this with your friends!!!

DeleteThanks again for your motivation.

thank you

ReplyDeleteYou are welcome!!!

DeleteThanks for sharing.

ReplyDeleteIt's very usefully.

You are most welcome and also thanks!!!

DeleteThanks for sharing.

ReplyDeleteIt's very usefully.

You are welcome and Happy Learning!!!

Deletedear sir thanks a lot please share pdf file

ReplyDeleteYou are welcome as of now we are working on this it will take a time.

Deletethank you very much for this article your all article are easy to understand the begineers

ReplyDeleteThank you very much for your kind words!!!

DeleteThank u sir. Good education material..

ReplyDeleteThank you very much for your kind words!!!

DeleteShivananda

ReplyDeleteThank u sir, good education material

Thank you very much for your kind words!!!

Deletei can't download the document, please could you help me

ReplyDeleteThanks for your query our team is working on the it will be available soon

DeleteIn a nutshell the whole IATF has been perfectly presented 👌👍👏

ReplyDeleteThank you for your kind words!!!

Delete

ReplyDeletereally appreciate your efforts to make manufacturing industry professionals better...👍👏

Thanks for your kind words and happy learning

DeleteHandling of Customer Complaint ?

ReplyDeleteYes you can read our article on 8D Methodology

Deletesir I need documents for HR Process. Can i get the formats for HR process

ReplyDeleteYes we can do needful you can reach us at: contact@nikunjbhoraniya.com

DeletePost a Comment