Top Lean Manufacturing & Lean Management Tools

→ Top Lean Tools are systematic and scientific approaches for problem-solving.→ Lean Tools are also used for identifying and eliminating waste from the system or process.

→ These tools are very important to implement a Lean Manufacturing culture in the factory.

➨ The list of top lean tools are:

- Kaizen

- Single Piece Flow

- Jidoka

- Poka Yoke

- Visual Management

- Kanban

- 8 Lean Wastes

- Six Big Losses

- Smart Goals

- Heijunka

- Just in time

- Takt time

- Bottleneck Analysis

- Andon

- Gemba

- Hoshin Kanri

- Overall Equipment Effectiveness (OEE)

- Cellular Manufacturing

- Total Productive Maintenance (TPM)

- Total Quality Management (TQM)

- Value Stream Study (VSM Study)

- Single Minute Exchange of Dies (SMED)

- Key Performance Indicators (KPIs)

- 5S Methodology

- Standardize work

- PDCA cycle

Kaizen or Continuous Improvement

What is Kaizen?

→ Kaizen stands for “continuous improvement” or “small incremental improvements” of all areas of a company.→ Kaizen word comes from the Japanese words “kai” which means “change or improvement” & “zen” which means “for betterment.”

→ The Lean tool Kaizen includes the involvement of all employees, from top management to bottom personnel.

Benefits of Kaizen:

→ It Improves processes by eliminating waste.→ Promotes personal growth of employees and the company.

→ Kaizen Improves quality, safety, cost structures, delivery, environments and it improves customer service/satisfaction.

How to implement Kaizen at our workplace:

➨ The Kaizen method is generally implemented in 5 different steps:⇢ Identify an area having a problem.

⇢ Analyze the data and method for the current process method.

⇢ Testing and evaluating improvement possibilities.

⇢ Implement improvements.

⇢ Analyze results and present them to top management for feedback.

Single Piece Flow or One Piece Flow

What is Single Piece Flow?

→ Single Piece Flow is the sequence of a product or service through a process that is the single unit is produced at a time.→ Single-Piece Flow is the opposite of batch production.

→ In batch production, there is a large number of products are processed at once.

→ Single-Piece Flow is focused on the manufacturing of the product itself rather than the waiting, transportation, and storage of the product.

Benefits of Single Piece Flow:

→ Single Piece Flow detects defects earlier and more accurately.→ In Single Piece flow, we can get more flexibility for customization and meeting customer demands.

→ It reduces costs by eliminating various lean wastes.

→ In Single Piece Flow we can easily predict the shipment timing.

Jidoka (Autonomation)

What is Jidoka (Autonomation)?

→ Jidoka means Autonomation→ Autonomation described as "intelligent automation" or "automation with a human touch"

→ Jidoka (Autonomation) refers to partially automate manufacturing.

→ Partial automation is typically much less expensive than full automation.

→ Jidoka implements some supervisory functions rather than production functions.

→ In this concept, the machine or line is automatically stopped when defects are detected.

Principles of Jidoka:

➨ The main principles of Jidoka are mentioned below.⇢ Detect the abnormality in the operation or product.

⇢ Stop the operation or product.

⇢ Fix or correct the immediate condition of the process or product.

⇢ Investigate the root cause and install a countermeasure in process or product.

Benefits of Jidoka(Autonomation):

→ Jidoka helps employees fix problems as they occur.→ It improves productivity.

→ Jidoka reduces downtime and breakdowns.

→ It empowers employees and machines.

Poka-Yoke

What is Poka-Yoke?

→ Poka-Yoke means Mistake Proofing or Error Prevention.→ Poka-Yoke prevents defects from being made or it highlights a defect so that it is not passed to the next operation.

Benefits of Poka-Yoke:

→ Poka-Yoke saves time and money by preventing defects or being made defective products.→ It is difficult to find all defects by inspection so we can use Poka-Yoke for effective and efficient operation.

→ Poka-Yoke prevents human error and it is a very important tool.

Visual Management

What is Visual Management?

→ Visual Management is a communication technique that uses visual aids to pass messages more effectively, more efficiently and very fast.→ Visual Management is the ability to manage everything in your factory or areas by visually.

Benefits of Visual Management:

→ Visual Management can display problems in a simpler way and very effective.→ Clearly indicates our targets and goals.

→ Visual Management can increase the effectiveness of communication.

→ Work instructions can be simplified by using the Visual Management Concept.

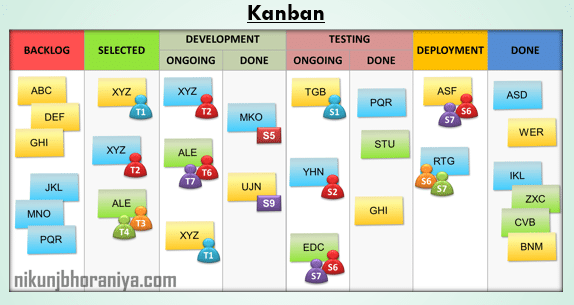

Kanban

What is Kanban?

→ Kanban means Signboard or Billboard.→ Kanban is a scheduling system for lean manufacturing and just-in-time manufacturing (JIT).

→ It takes its name from the cards that track production within a factory.

→ Kanban controls the inventory level at any stage of production.

Benefits of Kanban:

→ Kanban improves manufacturing efficiency→ One of the main benefits of kanban is to establish an upper limit to work in process inventory to avoid overcapacity

→ Kanban is an effective tool to support the running production system

→ Kanban reduces wastes.

8 Lean Wastes

➨ The 8 Wastes in Lean manufacturing are:

[1] Transportation waste:

⇢ Transportation is related to all unnecessary transportation activities within the organization.

[2] Inventory waste:

⇢ Inventory waste is related to all finished goods and in-process goods which are kept by us on because of the forecast and it is nonmoving.

[3] Motion waste:

⇢ Moving waste is related to people and equipment inefficiently moving between tasks.

[4] Waiting waste:

⇢ Waiting is how much time is consuming between your production steps in ideal condition.

[5] Over Production waste:

⇢ Over Production is that we are producing more products than customer's demand.

[6] Over Processing waste:

⇢ We are doing more operations to finish good products for that customer is not willing to pay.

[7] Defects waste:

⇢ The generation of defects in production is a total waste for that we have to spend on rework or repair or scrap.

[8] Skills sets (non-utilized talent) waste:

⇢ If we are not using our manpower efficiently then that is a waste.

Benefits of eliminating 8 Lean Wastes:

→ It increases productivity→ It creates a safer working environment

→ Reduce downtime

→ Improve efficiency and effectiveness

Six Big Losses

The six big losses are:

[1] Breakdowns or Unplanned Stops:⇢ It refers to mechanical failure and the need for maintenance or stoppage due to an unplanned activity like manpower are not available.

[2] Planned Stops or Setup/Adjustment:

⇢ Machines are stopped due to planned events, such as planned maintenance, safety inspections, or employee breaks and Setup/Adjustment refers to changeover and machine warm-up.

[3] Small Stops or Idling:

⇢ Small stops or Idling refers to machine stops for a short duration of time to correct settings, unclog jams, and routine cleaning activity.

[4] Speed or Slow Cycles:

⇢ Speed or Slow Cycles are referred to machine runs slower than designed, low efficiency of operator and machine wear down.

[5] Production Rejects or Defects:

⇢ Production Rejects or Defects are defective parts produced in the regular production, this is due to operator error or incorrect settings.

[6] Startup Rejects or Startup losses:

⇢ Startup Rejects or Startup losses are defective parts produced at the time of machine startups or during the operation or product changeovers

Benefits of analysis of Six Big Losses.

→ Six Big Losses provides us with a framework for eliminating the most common causes of waste in manufacturing.SMART Goals

What are SMART Goals?

→ The SMART goal is the method to set the goal or target in an effective manner.The goals should be clearly defined and communicated.

➨ The acronym SMART stands for:

⇢ S - Specific

⇢ M - Measurable

⇢ A - Attainable or Achievable

⇢ R - Realistic or Results-Focused

⇢ T - Time-bound

Heijunka

What is Heijunka?

→ Heijunka means Leveling or Balancing.→ It is used to minimize batching and create a more efficient manufacturing process.

→ It is a type of production scheduling and it supports a predictable and steady flow of small-batch manufacturing, instead of larger production processes used for goods and components.

Example of Heijunka:

→ Say a car manufacturer receives 1000 orders for cars every week. 200 on Monday, 100 on Tuesday, 100 on Wednesday, and 600 on Thursday. Instead of manufacturing 1000 cars at the beginning of the week or the exact amount needed each day, the company would produce exactly 200 cars per day. By producing the same amount every day, the factory can optimize the manufacturing operation for 200 cars and therefore create a more efficient process.Benefits of Heijunka:

→ Heijunka (Leveling or Balancing) improves efficiency at all levels of the manufacturing operation.→ It improves productivity and reduces the defects

→ Heijunka reduces inventories, working capital costs, manpower, and production lead time.

Just in Time

What is Just in Time?

→ It is focused on the production of customer's requirement like when they want it, how many quantities they want it, and where they want it?→ In this methodology, we produce the only customer's ordered quantity instead of creating a large stock of a product.

Benefits:

→ It reduces unnecessary inventory.→ Minimize the storage need and it gives companies flexibility in their manufacturing operations.

→ Save unnecessary expenses.

Takt Time

What is Takt Time?

→ It is the maximum amount of time requires to produce the product and satisfy the customer's demand.→ It is in other words: Net time available to work per unit of customer's demand or

→ Takt time (T) = Net time available to work (Ta)/Demand (customer demand) (D)

→ Where,

⇢ T = Takt time,

⇢ Ta = Net time available to work, e.g. [working 8 hours per day]

⇢ D = Demand (customer demand), e.g. [units required is 1000 qty per day]

Example:

→ If there are a total of 8 hours (or 480 minutes) in a shift (gross time) less 30 minutes lunch, 20 minutes of tea breaks (2 × 10 mins), 10 minutes for a meeting with team, then the net Available Time to Work = 480 - 30 - 20 - 10 = 420 minutes.→ If customer demand were 840 units per day and one shift was being run, then the line would be required to output at a minimum rate of two parts per minute in order to satisfy the customer's demand.

Benefits:

→ It keeps track of production rates→ It helps us to set real-time targets for production and reduces unnecessary wastes.

→ We can achieve a consistent flow of production by using takt time

→ We can eliminate the waste of overproduction by producing to meet actual customer demand.

Bottleneck Analysis

What is Bottleneck?

→ A Bottleneck means "constraint".→ The bottleneck in operation is understood by the stage of operation that takes the longest time in the whole operation

→ The bottleneck refers to the slowest member of the whole operation or it can determine the speed of the entire group.

→ If one part of the whole operation is slow, then it can reduce the speed of the whole operation.

→ Also, it reduces the efficiency of the entire manufacturing process.

Benefits of Bottleneck Analysis:

→ By removing bottleneck we can increase efficiency and profits.→ We can optimize the cycle time.

→ Increase productivity and plant capacity.

Andon

What is Andon?

→ Andon is a visual signaling system for the shop floor that indicates production status and alerts when assistance is needed→ Andon empowers operators to stop the production process if any abnormity found in product or process.

→ Usually, Andon uses a combination of lights and sounds to communicate any problem, production status updates, highlight the issues, and any achievements.

Benefits of Andon:

→ Andon brings an immediate response to problems as they occur→ It empowers operators

→ Andon keeps the shop floor person engaged with their tasks

Gemba

What is Gemba?

→ Gemba is a Japanese word.→ Gemba means "The Real Place".

→ It means the actual place where the problem was found or an incident has happened.

→ As per Gemba theory, we must have to go at the Gemba for investigation of any problem or incident.

→ So problem solver's or Cross function Team's presence is necessary at Gemba.

→ The actual place may be referred: In manufacturing, it is a shop floor or it can be a construction site, assembly line, any lab, office, etc....

Basic Principles of Gemba Walk:

➨ Basic Principles of Gemba Walk are mentioned below:⇢ Have a specific purpose of Gemba Walk.

⇢ Be familiar with the area that you are visiting.

⇢ Understand the overall process.

⇢ Correctly understand what you are seeing.

⇢ Know what to ask.

Benefits of Gemba:

→ By Gemba walk, we can get easily knowledge of the plant's productivity.→ Gemba gives a deep, thorough, and effective understanding of the manufacturing process and problems by observation and discussions with shop floor employees.

Hoshin Kanri

What is Hoshin Kanri?

→ Hoshin Kanri is a Japanese Word it means Policy Deployment→ The word "hoshin" means direction.

→ And The word "kanri" means administration.

→ In Hoshin Kanri, the strategic goals of the company are communicated throughout the company and then put into action with the help of middle management.

→ The top-down approach focus on steady communication for explaining visions, developing and implementing policy from top to bottom management, and receiving feedback from bottom to top management.

Benefits of Hoshin Kanri:

→ The Hoshin Kanri practice helps us to ensure that all employees within an organization are able to understand the organization’s vision.→ And all employees work toward a common goal of an organization.

→ It eliminates the waste that comes from poor communication and an unorganized direction.

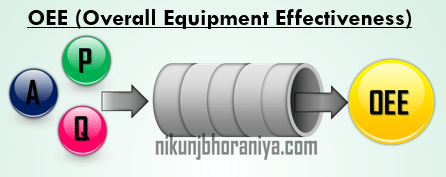

Overall Equipment Effectiveness (OEE)

What is Overall Equipment Effectiveness (OEE)?

→ OEE is a method used to measure manufacturing efficiency by using Performance Rate, Availability of Machine and Quality Rate.→ It measures the efficiency of Productivity in %.

→ With 0 % means zero productivity it means an inefficient production.

→ 100% OEE means perfect production (produced only good parts, as fast as possible, with no downtime).

→ OEE is calculated with the formula,

→ OEE= (Availability)*(Performance)*(Quality)

Benefits of OEE:

→ Knowing OEE helps us to find inefficiencies in the production cycle.→ It helps us to set goals for improvement, and track the progress.

→ OEE provides benchmark data for the new process setup.

→ OEE helps to track progress in eliminating waste from a manufacturing process.

Cellular Manufacturing

What is Cellular Manufacturing?

→ Cellular Manufacturing is creating process flow by dividing the full process into small sub-processes or steps.→ This small sub-processes or steps are called cells.

→ By combining these cells are called cellular manufacturing.

→ In Cellular Manufacturing the similar products are produced in the same cell.

→ The product moves through the whole process without any stoppage or any interruptions.

→ Commonly the cells are arranged in a "U-shape" design, this design allows a supervisor to move less and have more watch over the entire process.

Benefits of Cellular Manufacturing:

→ Cellular Manufacturing improves productivity and output→ Cellular Manufacturing reduces rejection and optimizes the floor space.

→ Quick change over possible

→ We can make a wide range of similar products in a single line.

→ Reduce lead time.

→ Enhance teamwork and communication between employees.

Total Productive Maintenance (TPM)

What is Total Productive Maintenance?

→ TPM is a well-defined system of maintaining and improving the production system and quality systems between the processes, machines, employees, equipment, and processes.→ TPM adds business value to an organization.

→ Total Productive Maintenance (TPM) focuses on proactive and preventative maintenance to maximize the operational time of equipment and reduce equipment failure rate as much as possible in order to increase production efficiency.

→ TPM completely removes the difference between production and maintenance by strong focuses on empowering operators to maintain their own equipment.

➨ The Eight Pillars of TPM:

- Autonomous Maintenance

- Focused Improvement

- Planned Maintenance

- Quality management

- Early/equipment management

- Education and Training

- Administrative & office TPM

- Safety Health Environment

Benefits of Total Productive Maintenance (TPM):

→ TPM Reduces downtime and increases productivity→ It Improves Quality

→ It creates a safer working environment

→ TPM Enhance teamwork and communication between employees and empower the operators

Total Quality Management (TQM)

What is Total Quality Management?

→ Total Quality Management is a customer-oriented process and it focuses on continuous improvement of Product, Process or Service of an organization.→ The goal of Total Quality Management (TQM) is to increase the quality at every single step in an organization.

The Principles of Total Quality Management:

→ Focus on customer→ Employee involvement

→ Process-centered

→ Integrated system

→ A strategic and systematic approach

→ Decision-making based on facts

→ Communication

→ Continuous improvement

Benefits of Total Quality Management:

→ Total Quality Management (TQM) will increase the awareness of quality within the organization.→ TQM establishes a quality-oriented culture within the organization

→ TQM emphasis on teamwork.

→ It will increase commitment towards continuous improvement within the organization.

Value Stream Mapping

What is Value Stream Mapping?

→ Value Stream Mapping is a method of analyzing the current state of a process and designs the future state of the process and it focuses on the opportunity for improvement by eliminating different wastes from processes.→ Value Stream Mapping includes the process, from the supplier end to reach at the customer end.

→ The process flow diagram is used to identify the waste and inefficiencies from the process in Value Stream Mapping.

Main Three Parts of Value Stream Mapping are:

→ Map Current State (Identify Waste)→ Design Future State

→ Create a Transformation Plan

Some common data collection points for Value Stream Mapping are:

→ The time is taken by one product or to pass one product from one station to the next station→ Level of Inventory

→ Number of operators

→ A number of shifts worked

→ Batch size

→ Change over and delivery time

→ Productivity etc...

Benefits of Value Stream Mapping:

→ Value Stream Mapping addresses underlying issues.→ It helps to identify wastes and eliminate wastes.

→ Value Stream Mapping helps to identify inefficiencies in the process.

Single-Minute Exchange of Dies (SMED)

What is the Single-Minute Exchange of Dies (SMED)?

→ Single-Minute Exchange of Die (SMED) is a method for reducing setup or change over time in a manufacturing process to less than 10 minutes.→ The efficiency of the operation or process can improve by reducing the setup or change over time in the factory.

→ The concept of SMED was given by Frederick Taylor in 1911 and it was used by Ford Motors in 1915.

Principles of the Single-Minute Exchange of Dies (SMED)?

→ Identify changeover tasks.→ Analyze each task to determine the purpose.

→ Determine low-cost solutions.

→ Implement that solution to reduce the changeover time.

Benefits of Single-Minute Exchange of Dies (SMED):

→ SMED improves efficiency→ SMED improves productivity

→ It gives more flexibility to production.

→ With the help of SMED, we can reduce inventory and enable a higher rate of production.

Key Performance Indicators (KPIs)

What are KPIs?

→ KPIs are essential metrics set by the management in order to check the success of lean manufacturing goals or performance of any process.→ Key Performance Indicators (KPI) are important for measuring efficiency, waste, and productivity.

Examples of common manufacturing KPIs are:

→ Speed→ Count

→ Cost of Poor Quality

→ Reject ratio

→ Customer Satisfaction Index or rating

→ MTBF, MTTR, etc.

Benefits of KPIs:

→ It helps to improve efficiency and productivity→ It helps management to define the roles and responsibility of employees

→ Create a vision, mission, and goals of an organization

→ It helps to set objectives and targets

5S Methodology

What is 5S Methodology?

→ 5S Methodology is a system for organizing spaces so work can be performed effectively & efficiently with safely.➨ 5S Meaning:

⇢ [S1] Seiri → Sort

⇢ [S2] Seiton → Set In Order

⇢ [S3] Seiso → Shine or Clean

⇢ [S4] Seiketsu → Standardize

⇢ [S5] Shitsuke → Sustain

Benefits of 5S Methodology:

→ Increase productivity through effectiveness→ Reduction in delays

→ Improved Quality

→ Improve in Safety

→ Set-up times reduced

→ Morale & Motivation Increase

→ Less stress for operators

→ Safer work environment

Standardized Work

What is the Standardized Work?

➝ The standardized work is documented procedures for any process.➝ It must be a live document so that it can be easily changed as per the modification of the process.

Benefits of Standardized Work:

➝ Better documentation of current operation flow.➝ Standardized Work helps to train the operator.

➝ Improvement in productivity and profits.

➝ Reduces variation in the operation flow.

➝ It adds discipline towards a work.

➝ Standardized Work promotes problem-solving.

➝ Standardize Work Increases teamwork across the organization.

PDCA Cycle

What is the PDCA cycle?

→ The PDCA Cycle is the Plan-Do-Check-Act Cycle.→ PDCA is a well-defined problem solving method and continuous improvement.

➨ The steps in the PDCA cycle are:

[1] Plan:

⇢ Problem is identified and all employees work together to develop a plan for making improvements or solving the identified problem.

[2] Do:

⇢ The plan is implemented as per the defined solution by a cross-functional team.

[3] Check:

⇢ Check the implemented solution and also discuss further improvements that can be possible or not?

[4] Act:

⇢ The implemented solution is documented if it has successfully solved the initial problem.

⇢ And If the solution is not satisfactory then again the cycle starts over at the Plan phase for finding out other factors.

Benefits of the PDCA Cycle (Plan-Do-Check-Act Cycle):

➝ It helps to implement Kaizen and other continuous improvement activities.➝ PDCA method Improves the brainstorming skills of your team

👉 See Also:

Hi. I can´t find the case study. Where are it?

ReplyDeleteHi You can go through the individual tool's post that is already available.

DeleteHow to download.

ReplyDeleteThe options is available to the individual article and for some article team is working on that.

DeleteA great blog which helps to know about an overview of the lean tools

ReplyDeleteThank you very much for your kind comment!!!

DeleteStill no download

ReplyDeleteThanks for your suggestion you can reach us at contact@nikunjbhoraniya.com

DeleteNo download, how to download ppt can you explain

ReplyDeleteOur team is working on that and also you can also reach us at contact@nikunjbhoraniya.com

DeleteReally good & useful information about lean

ReplyDeleteHi Thanks for the kind word and feedback

DeleteHi I want to become a member pls suggest how to do this

ReplyDeleteYou can join our social media platform for the regular updates!!!

DeleteVery nice and pls let me know how to get downloaded .

ReplyDeleteThanks!!!

DeleteHow to download such industrial content..? Great work done by you...👏

ReplyDeleteYou can connect us at contact@nikunjbhoraniya.com

DeleteIt's very helpful and development article to become great and more effective to discharging our duties.

ReplyDeleteYes you are absolutely right and thanks for your valuable feedback

Deleteprovided information is very &useful to improve work & knowledge.

ReplyDeleteThanks for your kind words and happy learning

DeleteThank you for your lessons.

ReplyDeleteYou are welcome and happy learning

DeleteCan you send me the pdf file of this information at my mail omani-@hotmail.com

ReplyDeleteYou can reach us at: contact@nikunjbhoraniya.com

DeleteDear All , Who needs this slide in PDF you can contact me omani-@hotmail.com

ReplyDeleteYou can connect with us at: contact@nikunjbhoraniya.com

Deletegreat

ReplyDeletePost a Comment