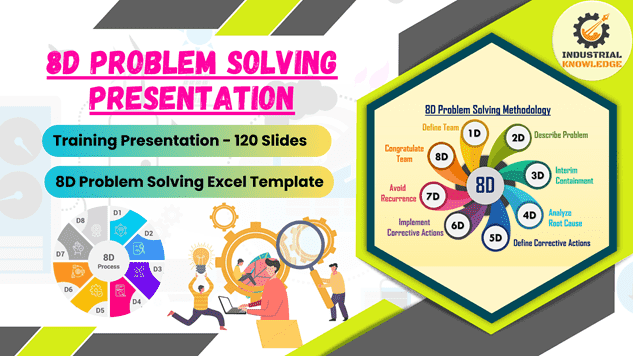

What is 8D Methodology?

→ 8D Methodology is a systematic problem-solving method.→ It was made popular by “The Ford Motor Company” in the automotive industry.

→ These are 8 disciplines or 8 steps that must be followed for identifying and eliminating a problem in a product, process, or service.

Eight Disciplines of Problem Solving:

- Establish the team

- Describe the problem

- Develop interim containment actions

- Define and verify root cause & escape points

- Choose and verify permanent corrective actions

- Implement and validate permanent corrective actions

- System prevention actions to prevent a recurrence

- Recognize team contributions

8D Problem Solving Example:

D1: Establish the Team:

➨ Purpose of D1:→ Establish a small group of people with relevant knowledge.

➨ Key activities of the team in D1:

→ Review priorities, scope, and problem

→ Identify how big a team is needed

→ Identify team members and establish the team

→ Nominate a team leader, project champion, and facilitator

→ Assign the roles and responsibilities

D2: Describe the Problem:

➨ Purpose of D2:→ Describe the internal or external issue by identifying “what is wrong with what” and detailing the problem in quantifiable terms so it is easy to take further action.

➨ Key activities in D2:

→ Develop a problem statement and a flowchart of all operation steps and identify critical operation steps with respect to the problem.

→ Establish a high-level project plan, including milestones, project goals, and objectives.

→ The description should define the boundaries.

➨ We can use the below tools to describe the problem.

→ 5W2H method

→ Why-Why Analysis

→ Check Sheet

D3: Develop Interim Containment Actions

➨ Purpose of D3:→ Define, verify, and implement interim containment action to isolate the effects of the problem from any internal and/or external customer until permanent corrective (preventive) actions are implemented.

➨ Key activities in D3:

→ Define the interim containment action

→ Verify the effectiveness of the interim containment action

→ Select and implement interim containment action

→ Validate the effectiveness of implemented interim containment action with the customer

➨ The containment actions must be implemented at the below location:

→ Customer's finished goods (FG) storage

→ At the customer's line

→ Customer's RM storage

→ Supplier's FG storage

→ At the Supplier's line

→ Supplier's RM storage

→ Also, check sub supplier's sequence of operation

➨ We can use the below tools for developing interim containment actions:

→ Why-Why Analysis

→ Check Sheet

→ Process Flow Diagram

D4: Define and Verify Root Cause & Escape Points:

➨ Purpose of D4:→ In this stage, the root cause is identified to take permanent action to eliminate the problem.

➨ Key activities in D4:

→ Development and verification of root_cause through data collection

→ Review process flow for the location of the root_cause

→ Determine the escape point

→ The escape point is the closest point in the process where the root cause could have been found but was not.

➨ We can use the below tools to define & verify root_cause & escape points

→ Fishbone or Ishikawa diagram

→ Why-Why Analysis

→ Check Sheet

→ Scatter Diagram

→ Process Flow Chart

D5: Choose and Verify Permanent Corrective Actions

➨ Purpose of D5:→ Select the best permanent corrective actions to eliminate the root cause in the process.

➨ Key activities in D5:

→ Develop and select the solution to remove the root cause & escape point

→ Verify the effectiveness of the selected solutions

➨ Six Mistake-Proofing Principles:

- Elimination

- Prevention

- Replacement

- Facilitation

- Detection

- Mitigation

➨ Various Mistake-Proofing Methods:

⇢ Variation Control

⇢ Workplace Organization

⇢ Identification

⇢ Process Checks

⇢ Poka-Yoke Devices

➨ Various Mistake-Proofing Devices:

⇢ Guide Pins

⇢ Error Detection & Alarms

⇢ Limit Switches

⇢ Sensors

⇢ Vision Systems

⇢ Counters & Timers

⇢ Checklists

➨ We can use the below tools for Choose and Verify Permanent Corrective Actions:

→ Fishbone or Ishikawa diagram

→ Why-Why Analysis

→ Check Sheet

→ Scatter Diagram

→ Process Flow Chart

→ PFMEA (Process Failure Mode and Effect Analysis)

→ Control Plan

D6: Implement and Validate Permanent Corrective Actions

➨ Purpose of D6:→ Plan and implement selected Permanent Corrective Actions

➨ Key activities in D6:

→ Implement the best solution to remove the root cause & escape point

→ Validate the effectiveness of the implemented action.

→ Monitor the effectiveness of the implemented solutions and assure that they do not cause any undesirable effects.

→ Communicate the plan to all relevant interested parties.

➨ We can use the below tools for implement and validate permanent corrective actions:

→ Cause and Effect Diagram or Fishbone

→ Why-Why Analysis

→ Check Sheet

→ Scatter Diagram

→ Process Flow Diagram

D7: System Prevention Action to Prevent Recurrence

➨ Purpose of D7:→ The purpose of the prevent recurrence is to share the knowledge, preventing_problems on similar products, processes, locations, or families.

➨ Key activities in D7:

→ Review similar products and processes for problem_prevention (Horizontal Deployment)

→ To update procedures and work instructions

→ Assure PFD, PFMEA, and Control Plan have been updated

→ Check the needing standardization has been identified and implemented?

➨ We can use below tools/documents to prevent recurrence:

→ Cause & Effect Diagram or Fishbone

→ Why-Why Analysis

→ Check Sheet

→ Scatter Diagram

→ PFD (Process Flow Diagram)

→ PFMEA (Process Failure Mode and Effect Analysis)

→ Control Plan

→ Work Instruction/SOP and Procedure

D8: Recognize Team Contributions

➨ Purpose of D8:→ Identify the lesson(s) learned and celebrate the success of the team.

➨ Key activities in D8:

→ Perform a final review of the problem-solving project

→ Prepare the report for future reference

→ Document the lesson learned

→ Before and after comparison of the issue

→ Recognize the team’s success and individual contributions

➨ We can use the below reports for the final stage in the 8D Methodology

→ 8D Report

→ Lesson Learned Report

→ Before and After Comparison of the issue

👉 See Also:

Very detailed explanation on 8D. Thanks

ReplyDeleteYou are most welcome!!!

DeleteHi, clear and detailed explanation. Thanks for that.Just want to know how to download the excel template. Could you pl support

ReplyDeleteThank you for your kind words.

DeleteThe download link is mentioned into this article itself so you can easily download from it.

How to download all this topic

ReplyDeleteSome of the topics are available for download for other we are working on that and the download link is available inside the article.

DeleteGreat website! Thank you for sharing your knowledge. This is a great learning source

ReplyDeleteThank you very much for your kind words!!!

DeleteVery useful

ReplyDeleteThank you very much!!!

DeleteGreat Information, Thank you!

ReplyDeleteWelcome and happy learning

DeleteUseful

ReplyDeleteThanks and happy learning

DeletePost a Comment