How is COPQ calculated?

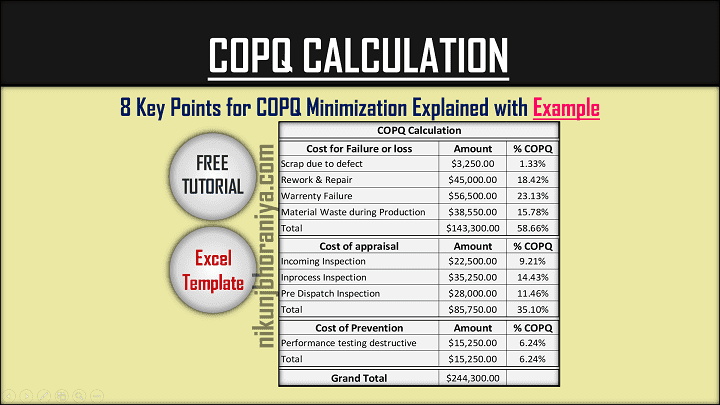

→ Now we will take one example of the Cost Of Poor Quality calculation in a tire manufacturing company you can apply the same concept for any organization. For a better understanding refer to the below picture in which the various costs mentioned are related to various COPQ activities.

How do you calculate the cost of poor quality in Excel?

→ For COPQ Calculation in Excel, you can easily download the template from the below-given link and by putting various costs related to poor quality into it you get the total value.👉 Read Complete article on the_COPQ

→ With the help of the Cost of poor quality analysis, we can prioritize the major cost spending area with the help of the Pareto Chart. Then we can find the root cause by Cause and Effect Diagram behind the cost spending and we can improve our efficiency and effectiveness.

How to Reduce COPQ? [Cost of Poor Quaity]

Key Points To Minimize COPQ:

- Traceability

- Nonconformity and Corrective Action

- Machine and Instrument Maintenance

- Internal Audit

- Change Management

- Customer Complaints Management

- Supplier Improvement Program

- Training and Empowerment of Employees

[1] Traceability:

→ If we want to reduce the_COPQ then traceability is one of the most important parameters that we have to maintain for our product and process.→ Without proper traceability, the organization faces problems like delays, defects, and recalls, etc.

→ If possible then it is better to implement the Poka-Yoke System within traceability from production to delivery. So we can easily view and access details on production location, time of production, warehouse, labeling and packaging, and delivery-related information.

[2] Nonconformity and Corrective Action:

→ Implement strong correction action for each and every nonconformity without any delay.→ The nonconformities may be in any form like production deviations, errors in specifications, or customer complaints, etc.

→ Record and maintain all action was taken on nonconformities like containment action taken, rework, replacement, discounts, or recall, etc.

→ We can use the below standard methodologies for root cause and corrective action:

⇢ 8D Problem Solving Method

⇢ 5S Methodology

⇢ 5 Why

⇢ Cause and Effect Analysis

⇢ FMEA, etc.

[3] Machine and Instrument Maintenance:

→ Various maintenance processes of various instruments and machines will help us to give conformity of our products continuously.→ Maintenance activity also reduces losses and minimizes failure.

→ So it maintains a smooth process flow.

[4] Internal Audit:

→ Internal audit is important for organizations to keep a record of non-conformities and corrective actions.→ This helps us to identify loopholes in our system that can be eliminated from the system.

→ We can implement various audits like factory audits, process audits, facility audits, QMS audits, and health & safety audits, which help in boosting the performance of the organization.

[5] Change Management:

→ Change management is also very important for the organization it can be any change related to technology, culture, operation, system, process, etc.→ Successful change management depends on strong leadership and clear policies of the organization.

→ Also, we have clear visibility into the whole process, including change history, data on the changes made, the status of changes made, and departments or areas affected, etc.

[6] Customer Complaints Management:

→ Effective customer complaints handling without any delay help us to satisfy our customer so we have happy customer.→ The happy customer gives us repetitive business and it will increase our top line as well bottom line.

→ Also, ensure that the same complaint will not repeat twice.

[7] Supplier Improvement Program:

→ The supplier's improvement program automatically improves our products.→ It helps us reduce our_COPQ by maintaining smooth process flow and eliminating all Wastes of the Manufacturing and Supply chain.

[8] Training and Empowerment of Employees:

→ The training and empowerment of employees also reduce the Cost Of Poor Quality in our organization.→ By providing periodic awareness sessions, training sessions, and evaluations for the same upgrade the knowledge of the employees and boosts their performances.

→ We can evaluate the effectiveness of the training by tests, questionnaires, and by giving practical tasks.

→ We can also apply the same for all stakeholders.

👉 See Also:

Thanks

ReplyDeleteGood input to reduce the COPQ. Some missing contains,

Appraisal – The costs associated with evaluation of materials, processes, products and services to ensure they conform to specifications. Costs can come from testing, measuring and auditing.

Internal failures – These costs happen when a defect is noticed and must get corrected before a product reaches a customer. They include scrapping materials, rework, equipment downtime and even injuries to employees.

External failures – These costs happen when a customer discovers an error. They can include repairs, time spent handling complaints and returns, and costs and employee time spent to fulfill a warranty.

Prevention – The costs associated with training, preventive maintenance, quality planning and other prevention activities.

In most cases, putting more money and effort into prevention will provide a better return on investment than handling the impact of poor quality in the manufacturing process. However, making the COPQ calculation is often necessary to show that this is the case.

Thank you very much for your time and sharing very much detailed study on COPQ

DeletePost a Comment