What is GRR Study (Gauge R&R)?

→ GRR Study (Gage R&R) is a methodology used to determine the amount of variation in the measurement data due to the measurement system.→ The full name of the GRR is Gauge Repeatability and Reproducibility which is a very important part of Measurement System Analysis.

GRR (Gauge R&R) Formula:

➨ Five Parameters of GRR (Gauge R&R) Study:

- Equipment Variation (EV)

- Appraiser Variation (AV)

- Gauge Repeatability & Reproducibility (Gauge R&R)

- Part Variation (PV)

- Total Variation (TV)

[1] Equipment Variation (EV):

→ This is the variance within the appraiser.→ EV measures the variance of an appraiser when measuring the same part (and the same characteristic) using the same instrument more than one time.

→ Calculation of EV

➨ Where K1 is a constant that depends on the number of trials.

⇢ For 2 trials, K1 is 0.8862.

⇢ For 3 trials, K1 is 0.5908.

[2] Appraiser Variation (AV):

→ AV is the variance between the different appraisers when measuring the same characteristic on the same part with the same instrument more than one time.→ Calculation of AV:

➨ Where K2 is a constant that depends on the number of appraisers.

⇢ For 2 appraisers, K2 is 0.7071

⇢ For 3 appraisers, K2 is 0.5231

[3] Gauge Repeatability & Reproducibility:

→ It is the combination of AV and EV or we can say that the vector sum of EV and AV, the calculation is given below.[4] Part Variation (PV):

→ The PV is calculated by multiplying the range of the part averages (Rp) by a constant K3.→ K3 depends on the number of parts.

→ The PV is then given by:

➨ Some other values of K3:

[5] Total Variation (TV):

→ This is the total variance of data recorded. We can calculate the TV by doing a vector sum of PV and GRR. It is determined by the following equation:GRR Study (Gauge R&R) Example with Excel:

- Determine the number of parts, appraisers, and trials

- Select the part & measuring instrument for the study

- Label the parts from 1 to n and designate the appraisers A, B, etc.

- Conduct the Measurements & put data into the Excel Template

- Analyzing the Results

- Interpreting the results

Step 1: Determine the no. of parts, appraisers, and trials:

→ The number of parts (n) must be greater than or equal to 5.→ The appraisers (k) must be greater than 2.

→ The number of trials (r) must be greater than or equal to two.

→ In addition, the n*k should be greater than 15.

→ This gives more confidence in the results.

Step 2: Select the parts & measuring instrument:

→ The next step is selecting the parts to include in the study.→ The parts should be selected to reflect the range of variation in the process. They should be selected in the proper method that they cover all possible variants of the manufacturing process.

→ In other words, don't just take 10 parts off the line right in a row.

→ If appropriate, calibrate the instrument or verify that the last calibration date is valid.

Step 3: Label the parts & designate appraisers A, B, etc.

→ Now we have to designate the appraisers and A, B, C, etc. and label the parts from 1 to n, but we have to take care of one thing that the appraisers must not aware of these things otherwise we can not get a proper resultStep 4: Conduct the Measurements & Put data into Excel:

→ The parts must be run in random order.→ All appraisers measures the reading each part 3 times.

→ Example trial1 – first in order, trial2 - second in reverse order, trial3 - third random).

→ Start with appraiser A - measures the parts in random order.

→ The results are recorded.

→ This process continues for each appraiser.

→ This cycle is continued until you have completed all trials.

→ Be sure that an appraiser cannot see his/her results from previous trials.

→ Open the above mentioned Excel worksheet to record data then enter the data related to your process.

→ Enter the number of operators, trials, samples and specification limits

Step 5: Analyzing the Results

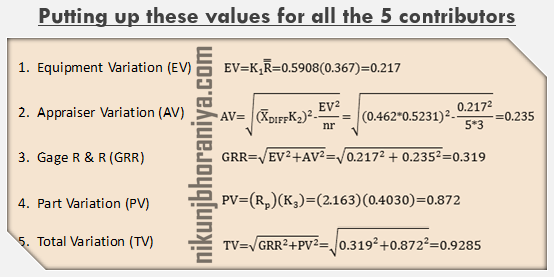

→ Analyze data in the Gauge R&R worksheet.→ In this analysis, we have selected three appraisers (A, B, and C) and five parts that represent typical variation in the length output.

→ All appraiser measures the reading each part 3 times.

→ The Calculation is mentioned in the below picture.

→ We use the above results for further calculation.

→ We start by determining the following:

→ The average for each trial for each appraiser

→ Average & Range of each part with each appraiser.

→ The average range for the part

➨ These calculations are shown in the table below.

➨ Determine the average range for the three appraisers

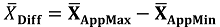

➨ Then, calculate the difference between the maximum and minimum of appraiser average.

→ Thus, the difference is (3.157) - (2.695) = 0.462

➨ Next, we will calculate the range of the part averages (Rp).

→ Here we subtract the largest average value minus the smallest average value.

→ So, Rp = (4.10) - (1.94) = 2.16

➨ Putting up these values into five parameters of Gauge R&R Study:

Step 6: Interpreting the results:

→ You must have variance in the parts and in the appraisers to calculate the above numbers.→ We have to check TV to decide that our measurement system is applicable or not?

→ The number that most people focus on first is the % GRR.

Gage R&R Acceptance criteria:

→ The following guidelines can be used to determine if the measurement system is acceptable, conditionally acceptable, or not acceptable.➨ Green: GRR % < 10% of TV (Measurement system is acceptable)

➨ Yellow: GRR % = 10-30% of TV (Conditionally acceptable based on the application)

➨ Red: GRR % > 30% of TV (Measurement system needs improvement)

→ In this example, the measurement system needs improvement since the value is greater than 30%.

→ Sometimes you can look at the %AV and %EV to get insights into where to start improving the measurement system.

→ But the study indicates that the measurement system must be improved.

NDC value in Gauge R&R Study:

➨ Also, we will check the number of distinct categories (ndc) in Gauge R&R Study.→ This is a measure of the number of distinct categories that can be distinguished by the measurement system.

→ It is similar to looking at how many possible values there are on a Range Control Chart.

→ The calculation is:

NDC = 1.41(PV/GRR) = 1.41(0.872/0.319) = 3.8

→ The integer value of NDC should be greater than or equal to 5.

→ In this case, it is 3.

→ Again, this is an indication that the measurement system needs improvement.

Correction Criteria of Measurement System Analysis:

➨ If Repeatability is large compared to Reproducibility, then the reasons may be:⇢ The instrument needs maintenance;

⇢ Other reason may be the instrument should be redesigned to be more rigid;

⇢ The clamping or location for gauging needs to be improved;

⇢ There is excessive part variance.

➨ If reproducibility is large compared to repeatability, then possible causes may be:

⇢ The appraiser needs to be better trained in how to use and read the instrument.

⇢ Calibrations on the instrument is not clear

⇢ A fixture may require to use the Gauge/Instrument in an appropriate manner.

Improvement points in Gauge R&R study in MSA

→ Brainstorm with the team for improvement solutions.→ Determine the best “practical solution” (may require some experimentation).

→ Pilot the best solution

→ Implement the best solution – train employees.

→ Again conduct the study to verify the Improvement.

👉 See Also:

Thank you for the explanation.

ReplyDeleteThank you for your feedback

DeleteSir if there are 4 vernier with callibration, is it necessary to perform Msa for all 4 vernier?

ReplyDeleteIf you are using all 4 verniers for measurement then it is mandatory to perform MSA for all.

DeleteThank you for the reply sir

DeleteYou are most welcome

DeleteAs per MSA std no. of trial should be moran than 90 readings.

ReplyDeleteAlso, we have to consider the customer's specific requirements

DeleteGood learning.

ReplyDeleteSir could you plz share bias and linearty study

It is already available you can search on google as "Bias Linearity Stability Study by Nikunj Bhoraniya".

DeleteSir,

ReplyDeleteThanks for nice learning.

How to decide , which variation is comes,

I.e. appraiser or measuring instruments

Pls confirm.

You can refer this article and also you can check our other article for your better understanding that is related to various types of variations.

DeleteOne more question,

ReplyDeleteNDC is only for cross verification the results , which comes in appraiser and instrument variation.

No, NDC is a part of the GRR study

DeleteIn this case AV is large as compared to EV , then on which we need to take actions

ReplyDeleteYou can go through it is already covered into the correction criteria section.

DeleteI was trained that we needed to use a d2 value when calculating Gage R&R values. Do you see a need for d2 during the calculations?

ReplyDeleteThe value of all constants are depends on the subgroup size. That is already covered into the article. Please go through the article and read carefully!!! Happy Learning!!!

DeleteWhere are you getting the values for K1?

ReplyDeleteWhere is the table for K3 located?

The value of all constants are taken from the table. Thanks for your suggesting we will update that table into our article.

DeleteWhat is nr?

ReplyDeletenr are two different variable.

Deleten = number of parts and r = number of trials.

So n=5 and r=3 in this example

Thanks for the very good question.

This is excellent training information. It is in-line with the MSA reference manual!

ReplyDeleteYes it is inline with MSA manual Thanks for your kind words!!!

DeleteSir, can i know the password of GRR study file

ReplyDeleteWe are working on that we will notify soon.

DeleteSir, Thank you for explaining nicely. Want to know what we do after we got the result that measurement system needs to be improved. What steps is needed to improve measurement system and how we do that. Thanks in advance.

ReplyDeleteHi thanks for the query we can do couple of things based on the result like - calibration of instrument, training of person, selection of the right instrument based on the 1/10 rule, etc...

DeleteSir, an you please explain about NDC?

ReplyDeleteThanks for your feedback we will definitely work on that.

DeletePost a Comment