What is Kaizen (Continuous Improvement)?

→ Kaizen comes from the Japanese words “kai” which means “change or improvement” & “zen” which means “for betterment.”→ Its popular meaning from Toyota is “continuous improvement” or “small incremental improvements” of all areas of a company, not just manufacturing.

→ It is a very famous Lean Manufacturing tool.

What is the Kaizen Event?

→ A Kai-Zen event should be part of an overall program of continuous improvement and It based on many small changes rather than fundamental changes. It does not require major capital investment or major process changes. The fundamental changes are related to Research and Development.→ As the ideas come from the workers themselves, they are easier to implement.

→ All employees should continually be seeking ways to improve their own performance.

→ It helps encourage workers to take ownership of their work and can help reinforce the team working, thereby improving worker motivation.

→ It is a very famous tool in Lean Manufacturing.

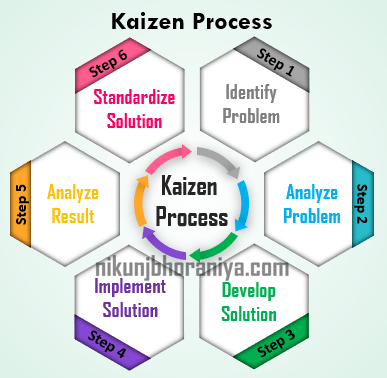

What is the kaizen process?

→ The Six Steps of the Kai-Zen process is mentioned below- Identify Problem

- Analyze the problem

- Develop an optimal solution

- Implement the solution

- Study and analyze the results

- Standardize the solution

What are the 3 pillars of kaizen?

- Good House Keeping & 5S

- Waste (Muda) Elimination

- Standardize

→ The Key Criteria are:

⇢ Does It reduce waste, Improve Quality, or Increase Safety?

⇢ Similarly, Does It Address the Root Cause?

⇢ Does It relate to Standardize?

History:

→ After World War II when Toyota first implemented quality circles in its production process.→ This was influenced in part by American business and management teachers who visited the country.

→ A Quality Circle is a group of workers performing the same or similar work, who meet regularly to identify, analyze, and solve work-related problems.

→ This revolutionary concept became very popular in Japan in the 1950s.

→ The term Kai-Zen actually became famous around the world through the works of Masaaki Imai.

→ Masaaki Imai is a Japanese organizational theorist and management consultant, known for his contribution to the betterment of industries.

→ He published two fundamental books on business process management.

What are the 5 elements of kaizen?

- Teamwork

- Personal discipline

- Improved morale

- Quality circles

- Suggestions for improvement

Principles of Continuous Improvement:

→ Improve everything continuously.→ Eliminate old and traditional concepts.

→ Accept the things, no give any excuses and make things happen.

→ Don’t Assume New Methods Will Work.

→ If something is wrong then correct it.

→ Empower everyone to take part in problem-solving.

→ Get information and opinions from multiple people.

→ Before making decisions, ask “why” 5 times to get to the root cause (5 Why Method) or we can use Cause and Effect Diagram for root cause analysis.

→ Be economical.

→ Never stop trying to improve

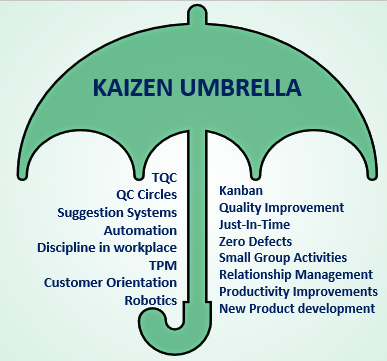

Kaizen Umbrella:

→ The elements of the Umbrella is:01. Total Quality Control (TQC)

02. Quality Circle

03. Suggestion System

04. Automation

05. Discipline in the Workplace

06. Customer Orientation

07. Total Productive Maintenance

08. Robotics

09. Kanban

10. Quality

11. Just in Time

12. Zero Defect

13. Small-Group Activity

14. Management Relations

15. Productivity

16. New Product Development

5W 1H of Kaizen:

→ The goal is production without wastes by improving standardized activities and processes.→ Industrial engineer Taiichi Ohno, father of the Toyota Production System (Lean Manufacturing), noticed that there is an 80% loss in every process and the value of the process is less than 20%.

What is "Kaizen eyes"?

→ "Kai-Zen eyes" see opportunities to improve.→ These eyes are a skill that can be developed through technique and practice

➨ Different Ways to develop “Kai-Zen Eyes”:

→ Put yourself in someone else's role→ Visit other places

→ Take the pictures

→ Draw the Value Stream Map

→ Ask yourself what normal should look like

→ Check the process

→ Audit the standard work (i.e. 5S Methodology)

→ Generate logic for continuous improvement and validate it.

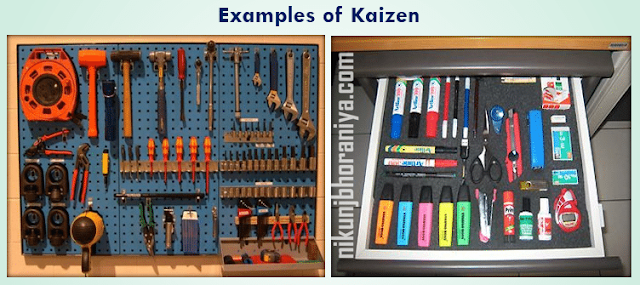

Kaizen Examples:

→ For better understanding refer below example.

→ Management's Role:

⇢ Communicate the need to change⇢ Demonstrate a personal commitment to improve

⇢ Educate and train the staff

⇢ Planning and implementation

Different Categories of Kaizen:

→ Different Category is mentioned below:⇢ Productivity

⇢ Quality

⇢ Safety

⇢ Cost Optimization

⇢ Moral

⇢ Delivery

⇢ Environment

Key Sucess Factor:

→ Employee Empowerment→ Training Provide from top to bottom

→ Focus on small incremental changes

→ Maintain documents for all before and after the improvement condition

→ Implement Standardized Work

→ Make an implementation plan related to your organization

→ Continuous repeat cycle: (1) Go to the workplace (2) Identify waste or problem (3) Implement Solution

Benefits of Kaizen:

→ Empowers employees to enrich the work experience and bring out the best in every person.→ Promotes personal growth of employees and the company.

→ Improves quality, safety, cost structures, delivery, environments and

→ It Improves customer service/satisfaction.

→ Improves teamwork and reduces wastes

→ Increase efficiency

👉 See Also:

Thank you for sharing industrial knowledge.....

ReplyDeleteVery good bro

Thank you for your kind word!!!

DeleteWant to Join WatsApp group but its full already pls create new one

ReplyDeletePlease Goto Home Page and try to join their...you can join it

DeleteThank you for your valuable feedback...We have solved your problem now you can easily join our group.

DeleteWhatsApp group is full, how can i join?

ReplyDeleteThank you for your interest!!! we have solved your problem now you can join our group.

DeleteI am not able to join the WhatsApp group...Can you add me by this number 7248850665

DeleteCould you share more examples on kaizen.. Please

ReplyDeleteThank you for your valuable feedback we will update it.

DeleteLove how simple, but thorough this is. I was unaware there were so many more "layers" of Kaizen. This has deepened my knowledge of kaizen and given me some new perspectives. Thank you.

ReplyDeleteThank you for your kind words

DeleteThank you for your kind words

DeleteThank you for sharing vital information. Your message is simply to understand and practice. Be blessed

ReplyDeleteThank you for your love, support and kind word

Deletecan i get any video or ebook of the same from your site?

ReplyDeleteAs of right now we do not have any video or ebook but we will plan for that

DeleteThanks for knowledge information sharing

ReplyDeleteThank you for your kind words

DeleteThank you for your kind words.

DeleteSir My Name is Badhusha.Working as a Deputy Manager-QA/QC(Mechanical).Thanks for sending mail through Industrial Knowledge.Please Continously send mail in mail id.How to join in your profile.Pleas tell me. Thank you sir for ssending mail to mail id regarding Industrial knowledge and thanks to NIKUNJ BHORANIYA.

ReplyDeleteThanks for your feedback you can join us: https://www.quora.com/q/industrialknowledge

DeleteLove your article. Tried joining your WhatsApp group to no avail

ReplyDeleteThanks for your valuable input. You can join our what's app group very easily link is available in our home page or you can refer this link: https://chat.whatsapp.com/Kg55Wjd8BxMF4gbbAuVB5v

DeleteCan I get as pdf format

ReplyDeleteHi thanks for your input. As of now some pdf format is available and rest will be available soon. Our team is working on that. We will notify soon.

DeleteThanks For clear explanation

ReplyDeleteThanks for your valuable feedback and kind words!!!

Deletecan i get the pdf or ppt for this ?

ReplyDeleteWe will work on that thanks for your feedback!!!

Deletethanks for sharing

ReplyDeleteYou are most welcome!!!

DeleteISSUES IN JOINING THE WHATSAP GROUP

ReplyDeleteHOWEVER THIS IS MY +224622734312

You can check the what's app joining link that is available on all pages of our website.

DeleteUnable to join whats app kindly fix it asap also I request you to upload pdf of all .

ReplyDeleteWe have fixed the what's app joining problem and also our team is working on the pdf file.

DeleteHi I like your content, but can you help me to make strategy roadmap of excellence, step of making Strategy roadmap? is there any PPT or PDF you have. please share here. looking forward to positive response. Thanks in advance.

ReplyDeleteThanks for your query our team will work on that and get back to your thanks for your time!!!

Deletesuperb! thank you for sharing

ReplyDeleteThanks and Happy Learning!!!

DeleteThank you very much..Nikunj boranjiya & Team.

ReplyDeleteFor providing such a valuable industry knowledge..! My doubt is in some downloaded blank ppt s are not able to edit..How Can we edit &use... please suggest if possible.

Hi thanks for the query - you can share that ppt to us at contact@nikunjbhoraniya.com and we will definitely help you.

DeleteFor example route cause analysis fish bone method.

ReplyDeleteYes thank you

DeleteThank u for sharing industrial knowledge, but I want to know how to download the article. . Thank u

ReplyDeleteYou can download from our websit or if you are facing any difficulty then mail us at: contact@nikunjbhoraniya.com

Delete👏👏👏

ReplyDeletePost a Comment