What is Muda Mura Muri in Lean Manufacturing?

→ The 3M technique in Lean Manufacturing is mostly used in the Toyota Production System.

→ The 3M stands for Muda, Mura, and Muri. This is a Japanese Concept.

→ The goal of Lean Manufacturing is to deliver increased value to the customer with the help of eliminating all kinds of waste from processes.

→ Now we will understand this concept with the help of examples and case studies.

What is Muda?

→ Muda means waste or we can say that any activity that consumes resources but not creating value for the organization or customer.

7 Types of Muda (Wastes) In Lean Manufacturing

→ The 7 types of Muda in lean manufacturing are mentioned below.

→ Refer to this article for a detailed presentation with the infographics of 7 Types of Wastes in Lean Manufacturing.

→ Nowadays one more waste is added into muda that is un-utilized talent or skill set.

- Transportation

- Inventory

- Motion or Movement loss

- Waiting

- Overprocessing

- Overproduction

- Defective Parts

→ We can eliminate all these wastes with the help of Various Kaizen Activities.

What is Mura?

→ Mura means unevenness in any process or schedule.

→ Unevenness can be eliminated by Line Balancing or Level Scheduling for any process.

→ We can also say mura means variation or fluctuation in any process.

→ Sometimes there are many fluctuations in product demand so it will directly reflect on the production planning fluctuations. This is the very basic example of Mura.

➨ Refer to the below basic examples of Mura

⇢ Uneven Customer Demand

⇢ Uneven Production Speed

⇢ Uneven Work Load Distribution

⇢ Product Quality is not consistent

What is Muri?

→ Muri means overburden on the equipment or on the person.

→ In other words, we can say that if we are running equipment on a higher load for a long time that is called overburden or muri.

→ Also, if we tell the operator to work long period of time without taking any breaks that are also overburdened.

→ We can see this kind of wastes when the product demand is increased at that time machine and operators are working on overburden like in extra shift.

→ So it will create the problems like breakdowns, defect generation, etc.

➨ Refer to the below basic examples of Muri

⇢ Working in overtime or for a longer time due to uneven customer demand

⇢ Noise level is very high in the working area

⇢ The machine is running out of capacity due to high customer demand

⇢ Overloading of truck

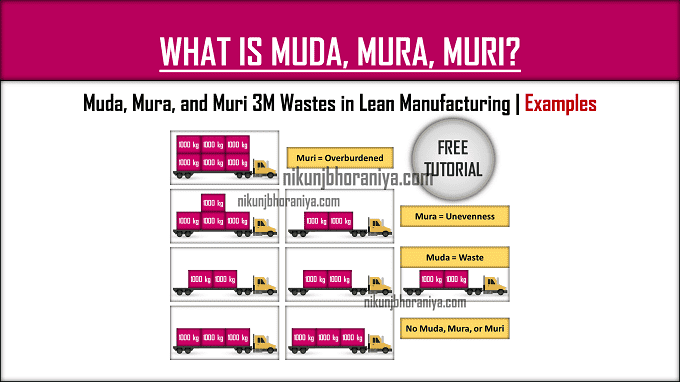

Example of Muda Mura Muri Wastes:

→ Let us take one real-life example for understanding this concept.

→ One logistic company needs to transport 6000kg of material from Location A to B.

→ So there are many transportation scenarios that are possible, out of that we will take three different cases for understanding the concept.

Case 01:

→ Transportation company load 6000kg material in a truck and make a single trip.

→ But the truck's load caring capacity is 3000kg.

→ So it is Muri types of waste. It is overburdened on the truck.

→ So truck might be leading to breakdowns.

Case 02:

→ We can take a second case If the truck makes two trips of 2000kg in the first trip and the second trip of 4000kg.

→ This is the case of Mura because there is the unevenness of materials arriving at the destination location.

→ Due to the unevenness of material sometimes it creates problems of handling and storage.

→ Also, it is an example of Muri - overburden on an operator to multiple time loading and unloading activity need to do that is due to two trips instead of a single trip.

→ So these wastes are not adding any value to the supplier or customer.

Case 03:

→ In the third case, we make three trips of loading 2000kg material on a single trip.

→ So this is an example of underloading of trucks.

→ So it is a Muda means waste.

→ The only way to eliminate all types of waste we need to arrange two trucks having a capacity of 3000kg and make two trips of 3000kg each.

How to eliminate Muda, Mura, Muri Wastes?

→ We can use below various Lean Manufacturing tools for eliminating all Muda, Mura, and Muri wastes.

Im learning too much from you guys. Thanks

ReplyDeleteThank you very much for your kind comment!!!

Deleteexcellent presentation

ReplyDeleteThanks!!! and happy learning

Deletegreat one. tks.

ReplyDeleteYou are most welcome

DeleteReally helpful. Excellent. Thank you.

ReplyDeleteYou are welcome happy learning

DeletePost a Comment