What is APQP [Advanced Product Quality Planning]?

→ APQP [Advanced Product Quality Planning] is a structured approach that is used to design and develop the product and process to meet customer needs and expectations.→ Advanced Product Quality Planning tool is extensively used by Automotive industries to assure quality and performance through effective planning.

→ In other words, APQP is a framework for developing new_product

→ More precisely we can say this method is rigorously used in the automotive industry.

→ This method is very much similar to the concept of Design for Six Sigma (DFSS).

→ As per AIAG, this tool is to help us to prepare a product quality plan to fulfill all requirements of the product and satisfy our customers.

→ APQP is one of the important tools among the Five Core Tools of IATF 16949 Standard.

History of APQP:

→ The "Big Three" [Ford, GM, and Chrysler.] developed the process of advanced product_quality planning in the late 1980s.→ Initially, the representatives from the Big Three and the Automotive Division of the American Society for Quality Control (ASQC) developed the guidelines for the Quality Requirements of automotive suppliers. This is a common criterion for all suppliers.

→ Today, APQP is adopted by many automotive industries.

→ Tier 1 suppliers of automotive OEMs are generally required to follow the APQP_guideline.

→ This will be audited during the certification of IATF16949.

→ The Automotive Industry Action Group (AIAG) is a non-profit organization of automotive companies founded in 1982.

→ This technique is being used in other manufacturing industries.

→ This is controlled and published by AIAG.

→ It is also known as the Five Core Tools of IATF 16949.

➨ The Five Core Tools of IATF 16949:

- Advanced Product Quality Planning - APQP_Manual

- Production Part Approval Process - PPAP Manual

- Failure Mode and Effect Analysis - FMEA Manual

- Measurement System Analysis - MSA Manual

- Statistical Process Control - SPC Manual

Objectives of APQP

→ Facilitate effective communication with everyone involved in the APQP process.→ Timely Completion of all required steps.

→ No or minimum quality complaints.

→ Assure product_quality, process_quality, and performance.

→ Meeting customer’s requirements

Main Focus Points of APQP

→ Understanding the customer's need & expectation→ APQP_focus on Proactive approach and corrective action

→ Designing within the process_capabilities

→ Analyzing and mitigating failure modes

→ Verification and validation and design_reviews

→ Control special/critical characteristics.

What is the APQP time plan?

→ The APQP_Time Plan is mentioned in the below picture.What are the 5 phases of APQP?

→ The Five Phases of APQP are mentioned below.- Plan & define program

- Product design & development

- Process Design_and Development

- Product and Process Validation

- Feedback, Assessment & Corrective Action

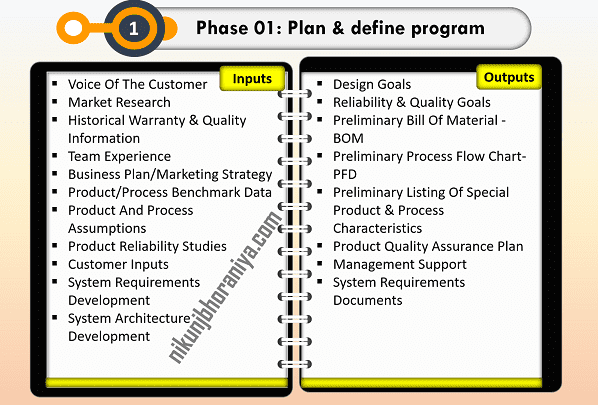

Phase 1: Plan & define program

→ The purpose of this_phase is to ensure that customer’s needs and expectations are clearly understood.➨ Inputs of this_phase:

- Understand the Voice of the customer

- Market research

- Historical warranty & quality_information

- Team experience

- Business plan/marketing strategy

- Product_& process_Benchmark data

- Product_& process_Assumptions

- Product_Reliability studies

- Customer inputs-such as Product_Identification & traceability, Special characteristics, and Packaging requirements, etc.

- Design_goals

- Reliability & quality goals

- Preliminary bill of material-BOM

- Preliminary process flow chart-PFC

- A preliminary listing of special_product & process_characteristics

- Product_Quality Assurance_plan

- Management support

Phase 2: Product design & development

→ The purpose of this_phase is to develop design features into nearly the final form of the product.➨ Inputs: Inputs of Phase_2 are the Outputs of Phase_1.

➨ Outputs of Phase 2:

- DFMEA – Design Failure Mode & Effects Analysis

- DFMA or DMA – Design for Manufacturability & Assembly

- DVP & R – Design Verification_Plan and Report

- Design Verification through Prototype Model

- Design verification through Product_Testing

- Prototype control_plan

- Engineering drawings review

- Engineering specifications review

- Material specifications review

- Drawing & specification changes

- Target setting for Productivity and Process_capability

- Gauge /Testing Equipment Requirements

- New Tooling/Equipment and Facilities requirement review

- Team Feasibility Commitment Sign off

Phase 3: Process Design and Development

→ The purpose of this_phase is to develop an effective management system to assure that customer’s needs and expectations are met.➨ Inputs: Inputs of Phase 3 are the Outputs of Phase 2.

➨ Outputs:

- PFD – Process Flow Diagram

- PFMEA – Process failure mode and effects analysis

- Pre-Launch Control_Plan

- Floor plan layout

- Packaging standards

- Measurement System Analysis_Plan

- Data for Quality, Reliability, Measurability, and Maintainability

- Method of rapid detection and feedback

- Result of Error-proofing activities

Phase 4: Product and Process Validation

→ The purpose of this phase is to validate the manufacturing process with the help of a production trial run and to finalize the Production control plan.➨ Inputs: Inputs of Phase 4 are the Outputs of Phase 3

➨ Outputs:

- Production Trial Run

- Production control plan

- Measurement systems evaluation

- Preliminary Process_capability study

- Production part approval – PPAP

- Production validation testing

- Packaging evaluation

- Quality_planning sign-off and management support

Phase 5: Feedback, Assessment & Corrective Action

→ The aim of this phase is to make continual improvements in the product and Process to enhance customer satisfaction levels.➨ Inputs: Inputs of Phase 5 are the Outputs of Phase 4.

➨ Outputs:

- Reduced Variation (Common and Special cause of Variations)

- Improved Customer Satisfaction

- Improved Delivery and Services

- Effective Use of Lessons Learn/ Best Practices

- Activities include in this phase to enhance customer satisfaction are:

- Evaluation of the Effectiveness of APQP_Efforts based on customer feedback.

- Making the necessary changes to correct non-conformance/deficiencies.

- Continuation of Customer and Supplier partnership.

- Organizational participation in problem-solving and continuous improvement activities.

- APQP_Timing Chart

Benefits of APQP

→ Increase Customer Satisfaction Level→ Early identification of required changes

→ Changes after product_launch are avoided

→ On-time delivery of quality_products with competitive prices.

👉 See Also:

Thanks for valuable information about our own knowledge development

ReplyDeleteThank you for your kind words.

DeleteWhow!

ReplyDeleteThanks!!!

Deleteplease share template if you have.

ReplyDeleteTemplates are already available on our website your can check all related articles and you will definitely find it

DeleteHow to download no link or button available

ReplyDeleteYou can reach us at contact@nikunjbhoraniya.com

DeleteCould you please share the PDF copy of the same.

ReplyDeleteSure we will

DeleteVery profound please share to mboneni.hGmail.com

DeleteVery nice explanation

ReplyDeleteThanks and happy learning

DeleteVery helpful for interviews.

ReplyDeleteVery happy to hear that. thanks for your kind words and happy learning.

DeleteHow does one get a copy of some of your APQP charts. Thanks

ReplyDeleteYou can reach us at: contact@nikunjbhoraniya.com

DeletePost a Comment