Control Chart Rules, Patterns, and Interpretation

➝ Control Chart Rules, Patterns, and Interpretation are helping us to identify the special cause of variation in the process.➝ By referring to these 8 rules, we can identify and eliminate the cause of variation and make our operation smooth.

➝ It is a statistical tool used to differentiate between process variation resulting from a common cause & special cause.

👉 Check this article for, Complete understanding of the Fundamentals of what is Control Chart? | Types of the Control Chart | Make your chart in easy 8 steps.

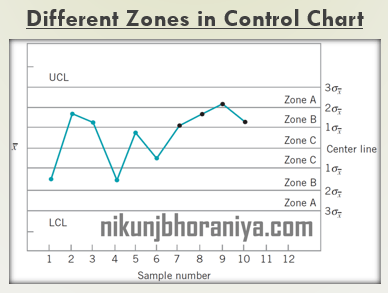

Different zones in the control chart

➝ Now, first of all, we define the zone for understanding the Control Chart Rules.➝ Please show the below picture for a clear understanding of UCL, LCL, Centreline, and different Zone A, Zone B, and Zone C.

➝ Each zone has a distance of one sigma.

➝ From the center line add one sigma for each zone.

Eight Control Chart Rules

➝ The Eight different rules are mentioned below (Source: AIAG – (SPC) 2nd Edition)- One or More points are more than 3𝝈 from the center-line

- 7_points in a row on the same side of the center

- 6_points in a row increasing or decreasing steadily

- 14_points continuously alternating up and down

- 2 out of 3 consecutive points > 2𝝈 from the center-line (same_side)

- 4 out of 5 consecutive points > 1𝝈 limit from the center-line (same_side)

- 15_points in a row within 1𝝈 of the center-line (either_side)

- A run of 8 consecutive points > 1𝝈 from the center-line (either_side)

Rule 1: One or More points are > 3𝝈 from the centerline

→ It is also called a point beyond the central line.→ Sometimes, Rule 1 also known as a large shift from the average.

→ If we can get any point beyond the control line then the special cause is available.

➨ Possible Causes:

⇢ The new person doing the job

⇢ Wrong setup

⇢ Measurement error

⇢ Operation step skipped or not completed

⇢ Power failure

⇢ Equipment breakdown

Rule 2: 7_points in a row on the same side of the center

→ It is known as a Small shift from the average.→ If we get continuously 7_points on the same side of the centerline then the special cause is available in the process.

➨ Possible Causes:

⇢ Raw material change

⇢ Change in work instruction

⇢ Different measurement devices/calibration

⇢ Different shift

⇢ A person gains greater skills in doing the job

⇢ Change in the maintenance program

⇢ Change in the setup procedure

Rule 3: 6_points in a row steadily increasing or decreasing

→ It is known as a trend pattern.→ If we get a pattern of 6_points continuously in increasing order or decreasing order then the special cause is available in the process

➨ Possible Causes:

⇢ Tooling wear

⇢ Temperature effects (cooling, heating)

Rule 4: 14_points continuously alternating up and down

→ This is also known as an overcontrol pattern→ If we get 14 points in a row up and down then the special cause is available in the process.

➨ Possible Causes:

⇢ Tampering by the operator

⇢ Alternating raw materials

Rule 5: 2 out of 3 consecutive points > 2𝝈 (same_side)

→ It is also known as a large shift from the average.→ If we get 2_points out of consecutive 3_points present in >2-sigma distance from the center-line on the same side then the special cause is present in the process.

→ In other words, 2 out of 3 consecutive points are present in zone A (same side of the center-line).

➨ Possible Causes:

⇢ The new person doing the job

⇢ Wrong setup

⇢ Measurement error

⇢ Operation step skipped or not completed

⇢ Power failure

⇢ Equipment breakdown

Rule 6: 4 out of 5 consecutive points > 1𝝈 (same side)

→ It is known as a Small shift from the average.→ If we get 4_points out of consecutive 5_points present in >1-sigma distance from the centerline on the same side then the special cause is present in the process.

→ In other words, 4 out of 5 consecutive points are present in Zone B or beyond (same side of the centerline).

➨ Possible Causes:

⇢ Raw material change

⇢ Change in work instruction

⇢ Different measurement devices/calibration

⇢ Different shift

⇢ A person gains greater skills in doing the job

⇢ Change in the maintenance program

⇢ Change in the setup procedure

Rule 7: 15_points in a row within 1𝝈 (either side)

→ This is also known as the stratification nature of the pattern.→ If we get 15_points in a row within 1 sigma of the centerline or within zone C (any side of the central line) then the special cause is available.

➨ Possible Causes:

⇢ Data mixed with more than one process.

⇢ Mixed data of more than one shift, machines, or raw materials

Rule 8: A run of 8 consecutive points > 1𝝈 (either side)

→ This is also known as a mixture property of pattern.→ If we get 8 consecutive points > 1 sigma from the centerline (either side) then the special cause is available.

→ In other words, 8 consecutive points with no points available in zone C (any side of the centerline).

➨ Possible Causes:

⇢ Data mixed with more than one process.

⇢ Mixed data of more than one shift, machines, or raw materials

Summary of Control Chart Rules:

→ It is very difficult to list out all possible special causes for each pattern.→ Because special_causes are very dependent on the type of process.

→ Manufacturing processes have different issues and service-related processes have different issues.

→ For, understanding purposes, some possible causes which are responsible for the special_cause of variation and identified by chart pattern are mentioned in the below table.

👉 See Also:

👍

ReplyDeleteThanks!!!

DeleteNice structure and content

ReplyDeleteThank you very much for your appreciation

DeletePost a Comment